Oxygen sensors

We differentiate between two typical oxygen measuring systems:

- Inline Oxygen Measuring

- Extractive Oxygen Measuring

Sensors, which extend into the process, are called inline sensors.

Sensors, which require measuring gas to be taken from the process, are called extractive sensors.

In order to account for the manifold measuring requirements and conditions at the measuring locations, our many years of experience have led us to develop a number of versions of oxygen sensors and electronic measuring devices.

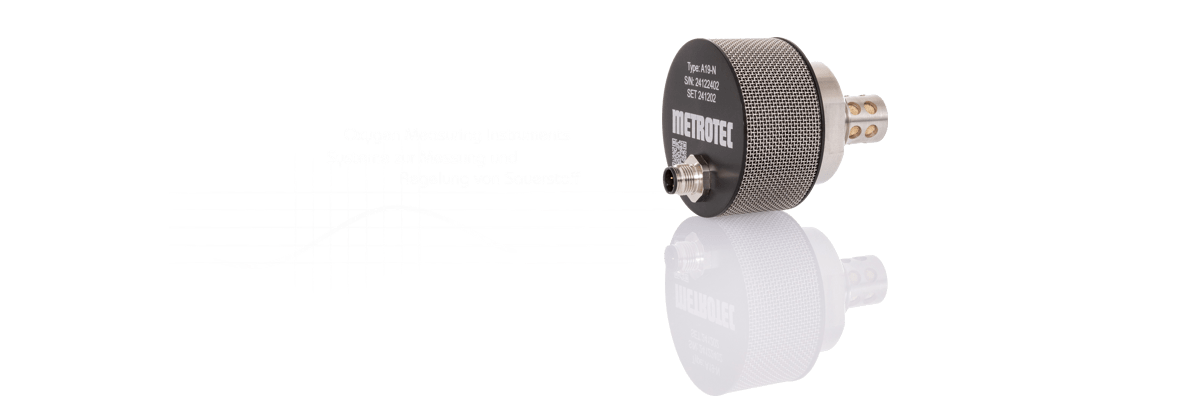

Oxygen sensor A19-N

The A19-N/NC oxygen sensor, part of the A series, is a universally applicable oxygen sensor for measuring oxygen.

The measuring principle of the A19-N/NC is based on a heated zirconium oxide, which generates an oxygen partial pressure using the Nernst principle.

The A19-N/NC is designed for measurement in the measuring chamber.

A supply module is required for the sensor to function.

Downloads

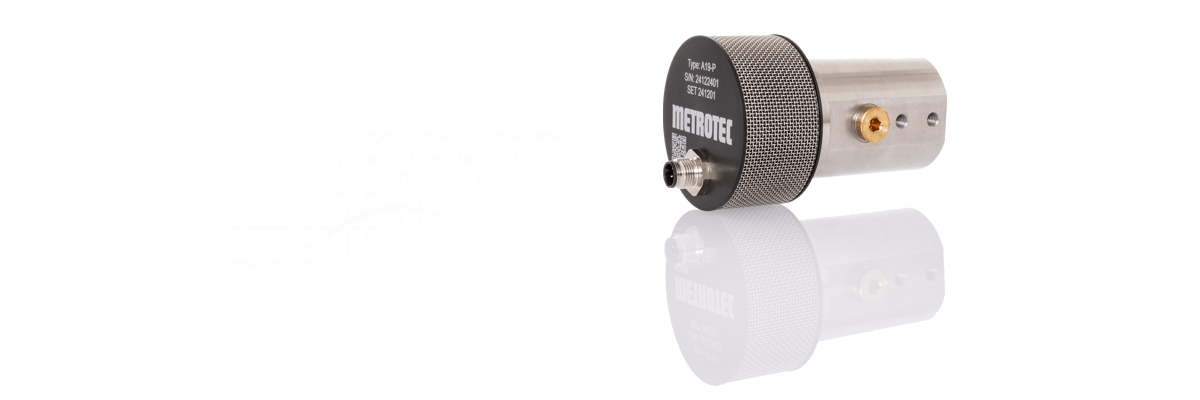

Oxygen sensor A19-P/PC

The A19-P/PC oxygen sensor, part of the A series, is a universally applicable oxygen sensor for measuring oxygen.

The measuring principle of the A19-P/PC is based on a heated zirconium oxide, which generates an oxygen partial pressure using the Nernst principle.

The A19-P/PC is designed for measurement outside the measuring chamber.

A sample gas pump or system overpressure must ensure the gas flow.

A supply module is required for the sensor to function.

Downloads

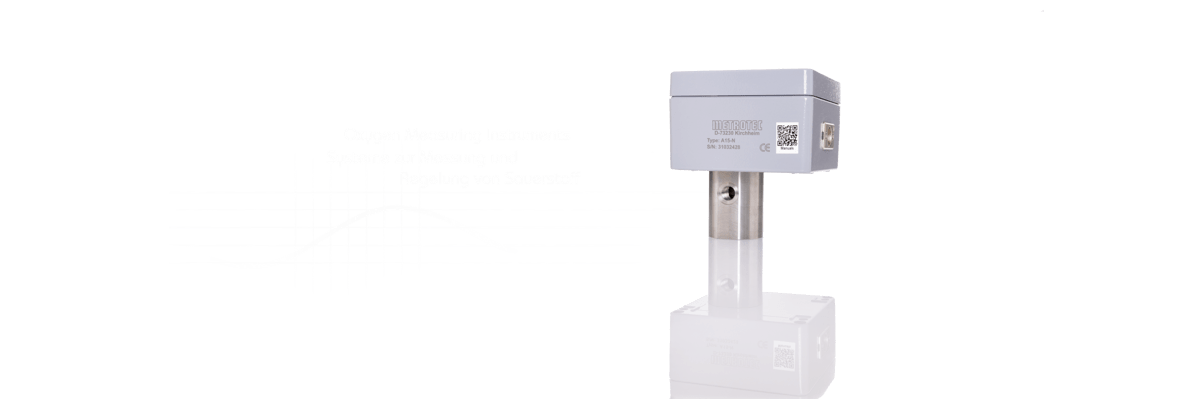

Oxygen sensor A15-N

The A15-N oxygen sensor, part of the A series, is a universally applicable oxygen sensor for measuring oxygen.

The measuring principle of the A15-N is based on a heated zirconium oxide, which generates an oxygen partial pressure using the Nernst principle.

The A15-N is designed for measurement outside the measuring chamber.

A sample gas pump or system overpressure must ensure the gas flow.

A supply module is required for the sensor to function.

Downloads

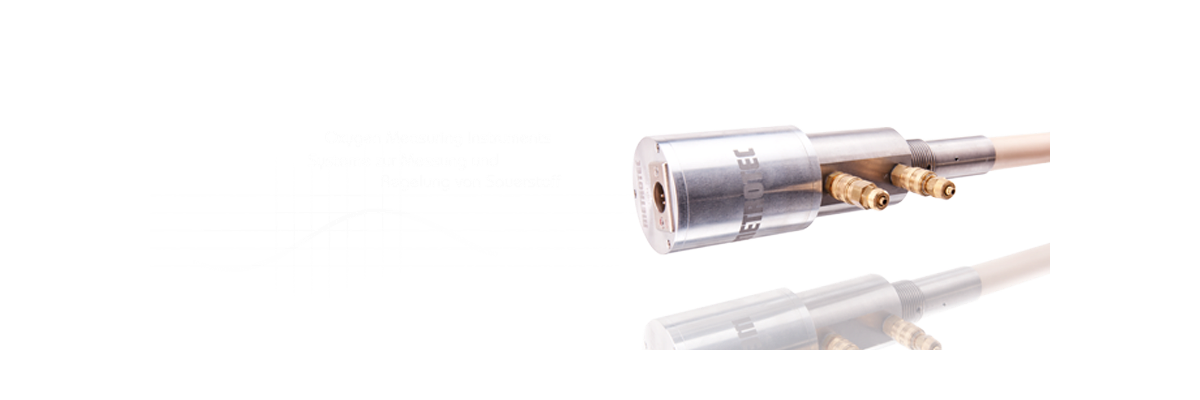

Oxygen sensor CMM / CSM

The CSM oxygen sensors, with a ceramic protection tube, and the CMM oxygen sensors, with a metallic protection tube, of the C series, were specifically developed for inline measurement.

These oxygen sensors measure directly in the high-temperature process.

Zirconium oxide as the measuring principle allows excellent interpretation during heat treatments, especially in the areas of oxidation, reduction, and carburization.

High-alloy stainless steel or special ceramics guarantee long-term stability and corrosion protection.

Additionally, each C series sensor features an integrated Type S thermocouple.

A19-N Manual (PDF)

A19-N Manual (PDF)